Amorphous, Custom Nanocrystalline, & Nickel Iron Cores

A MORE Powerful Solution

As MH&W International continuously strives to be the leader for offering powerful solutions in the magnetics industry, MH&W has partnered with a leading OEM supplier of amorphous cores, custom nanocrystalline cores, and 80% nickel iron alloy cores. The core configurations include toroids, gapped toroids, cut cores, and specialty stampings. With the addition of these products, MH&W will be able to offer the marketplace competitive prices on low frequency magnetics designs in addition to the high frequency magnetics designs currently being supported

Amorphous Ribbon

Amorphous metals do not have crystalline structures like other magnetic materials. All the atoms in an amorphous metal are randomly arranged, thus giving it a higher resistivity (about three times) value than that for crystalline counterparts. Amorphous alloys are prepared by cooling the melt at about 1 million degrees per second. This fast cooling does not give the atoms enough time to rearrange into stable crystalline form, resulting in a metastable amorphous structure. Because of the absence of crystalline structures, amorphous alloys are magnetically soft (lower coercivity, lower core loss, higher permeability) with high resistivity giving lower losses at higher frequencies. The losses are among the lowest of any known magnetic materials.

Characteristics:

High saturation induction of 1.56 Tesla – Reducing component volume

Low coercivity – Increasing component efficiency

Low core loss- Reducing temperature rise in devices

Variable permeability by different heat treatments – Satisfying various application requirements

Excellent thermal stability – Having highest service temperature of 130°C

Physical Properties:

| Saturation Induction Bs | 1.56T | Hardness Hv | 960kg/mm2 |

| Curie Temperature Tc | 410 ⁰C | Density | 7.18g/cm3 |

| Crystallization Temperature Tx | 535 ⁰C | Resistivity | 130 µ Ω · cm |

| Saturation Magnetostriction | 27 X 10-6 |

Applications:

Medium-frequency transformer cores in heating equipment

Toroidal gapless cores as SMPS output inductors and differential input inductors

Toroidal gapless cores as noise prevention chokes in automotive audio and navigation systems

Toroidal gap cores for PFC used in air conditioner and plasma TV

High-frequency rectangular cut cores as output inductors and transformers in SMPS, UPS, etc.

Toroidal gapless cores as pulse transformers for driving IGBTs, MOSFETs, and GTOs

Amorphous stators and rotors in high power density speed-variable electric motors and generators

Available Shapes, Features, & Applications

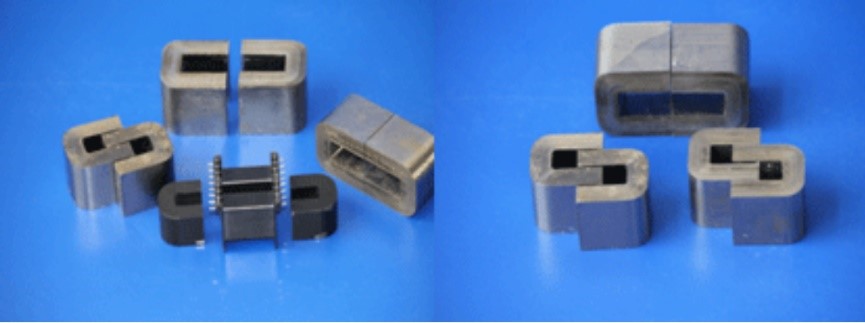

Amorphous Cut Cores –MH&W’s amorphous cut cores are available in the standard ACC sizes along with custom configurations.

Features:

High magnetic induction saturation

Low core loss

Good temperature stability, -55 °C- 130°C

Ease of assembly versus laminations

Applications:

Output choke coil for SMPS

Choke coil for DC/DC converter

Normal mode choke coil

Choke coil for adapter and battery charger

PFC choke coil

Uninterruptible Power Systems

click here for a table of standard ACC sizes or contact MH&W for custom sizes.

Amorphous Choke Cores – MH&W’s amorphous choke cores are available in standard and custom sizes with plastic cases, epoxy coating, or varnish impregnated.

Features:

High magnetic induction saturation

Low core loss compared to other core materials

Good frequency and temperature characteristics, usable to 300KHz

Good DC bias characteristics

Low leakage flux Space saving and lighter weight, compared to other cores

Applications:

Output choke coil for SMPS

Choke coil for DC/DC converter

Normal mode choke coil

Choke coil for adapter and battery charger

PFC choke coil

click here for a table of standard sizes or contact MH&W for custom sizes.

Amorphous Choke Cores with Air Gap – MH&W’s amorphous choke cores with air gap are available in standard and custom sizes with plastic cases, epoxy coating, or varnish impregnated.

Features:

Large DC bias characteristics

Permeability (µ):180- 200

Good frequency and temperature characteristics

Low core loss

Applications:

Output choke coil for SMPS

Choke coil for DC/DC converter

PFC choke for UPS, Inverter circuits, and PDP TV

Choke coil for adapter and battery charger

click here for a table of standard sizes or contact MH&W for custom sizes.

Nanocrystalline Ribbon

Nanocrystalline ribbon is based on Fe, Si, and B with additions of Nb and Cu. As with amorphous ribbon, it is produced by a rapid cooling process into a thin ribbon, initially in the amorphous state, and then crystallized in a subsequent heat treatment around 500 – 600 °C. This results in an extremely fine-grained microstructure with grain sizes of 10 nanometers, hence the name nanocrystalline.

These nanocrystalline alloys combine low magnetic anisotropy and low magnetostriction, both of which are prerequisites for high magnetic permeability with high magnetic flux density (Bs), and good thermal stability.

High saturation magnetic flux density

High permeability

Low coercivity

Low loss and good stability

Physical Properties:

| Saturation Induction Bs | 0.25T | Hardness Hv | 880kg/mm2 |

| Curie Temperature Tc | 560 ⁰C | Density | 7.2g/cm3 |

| Crystallization Temperature Tx | 510 ⁰C | Resistivity | 130 µ Ω · cm |

| Saturation Magnetostriction | 2 X 10-6 |

Applications:

Nanocrystalline ribbon can replace silicon steel, permalloy, and ferrite, as various forms of high frequency (20kHz-100kHz) cores used in:

Switching power supplies

Control transformers

Filter inductors

Reactors

Magnetic amplifiers

Saturable reactor cores

Common mode EMC filters

Differential mode inductors

ISDN miniature isolation transformers

Precision current transformers

Available Shapes, Features, & Applications

Custom Nanocrystalline Cores:

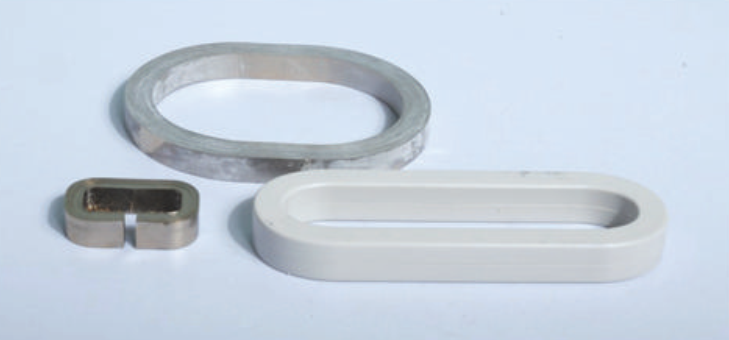

Custom Nanocrystalline cores are available from MH&W and are typically used for Large Toroidal Power Transformers, Current Transformers in Power Systems, Current Transformers, Common Mode Chokes, and MAG-AMPS. These cores are available encased in a plastic core cup, epoxy coated, or varnish impregnated. As with the Amorphous Choke Cores with Air Gap, the Nanocrystalline Cores are available with an air gap for Hall Effect devices and applications. MH&W can offer a competitive cross reference to almost any nanocrystalline core manufacturer’s cores.

Contact MH&W with your custom or standard requirements.

DC Immunity Composite Cores:

DC Immunity Composite Cores are made up of both nanocrystalline ribbon and amorphous ribbon material, allowing the core to operate effectively as a current transformer under DC current conditions. Features: Strong DC current immunity Applicable Current range 1.5 – 200 A Good temperature stability Applications: DC current immunity transformer in electronic energy meters / watt-hour meters Metering transformer in electronic power systems

click here for a table of standard sizes or contact MH&W for custom sizes.

Perm-alloy Ribbon:

Perm-alloy Ribbon Perm-alloy is a highly magnetic nickel-molybdenum-iron alloy, with roughly 80% nickel, 15% iron, and 5% molybdenum content. It’s useful as a magnetic core material in electrical and electronic equipment.

Features:

High initial and maximum permeabilities

Low coercive force

Low hysteresis loss

Low eddy-current losses

Low magnetostriction

High linearity and precision

Applications:

Output choke coil for SMPS

Choke coil for DC/DC converter

Normal mode choke coil

Choke coil for adapter and battery charger

PFC choke coil

GFCI/RCD sense coil

EE, EL, and L stamped or laminated magnetic cores, and C and oval cores with special shapes according to customer’s requirements.

Physical Properties:

| Material | Density | Curie Temperature | Coercivity | Remanence | Saturation |

| g/cm3 | ℃ | Hc (A/M) | Br (T) | Bs (T) | |

| Ni80Fe alloy | 8.75 | 400 | 2.1 | 0.24 | 0.8 |

click here for a table or standard sizes or contact MH&W for custom sizes.

Call today for a quote.