The new COOL BLUE range completes MAGNETEC’s series of high performance toroids made from the nano-crystalline material NANOPERM. Available are cores up to 500 mm (!) outer diameter and several space saving stadium-shaped (oval) variants.

The cores of the new series feature significantly improved high frequency performance due to a permeability level several times higher than any kind of ferrite. In Europe, COOL BLUE cores are being used increasingly to reduce damaging bearing currents of modern inverter systems of the latest generation (doubly fed induction generators (DFIG) IGBT technology) from apprx. 500kW up to about 5 MW. As a consequence of those parasitic currents, the bearings corrugate followed by electrical breakdown of the lubrication which soon causes an early failure and standstill of the whole motor. The same effect occurs in modern wind energy generators, even though the direction of the energy flow is reversed in this application. Some of the leading European Wind Turbine manufacturers have successfully designed in the new COOL BLUE cores recently because it is technically the most effective and proven solution to a severe problem and provides the best value for the money at the same time. The COOL BLUE solution is significantly cheaper than isolating hybrid bearings.

With those high-tech cores not only the over voltage peaks at the winding terminals are significantly reduced, but also the asymmetrical EMI currents which both are generated by the parasitic capacities of the interconnecting cables and the motor/generator itself.

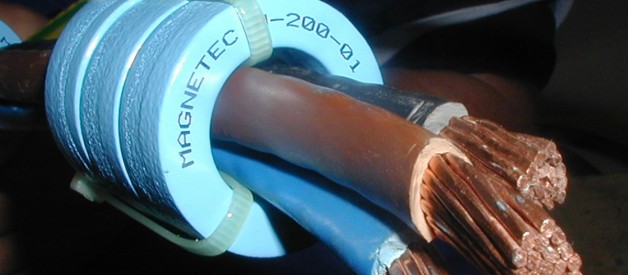

In order to achieve an efficient reduction of those destructive effects, several nano-crystalline cores of suitable geometry have to be put commonly over the connector cables each in the DC-link and/or at the inverter output. In this configuration, the cores operate as common-mode chokes. This method significantly increases the service life of the generator bearings and thus significantly reduces maintenance costs and costly standstill periods.

Summary of the advantages of COOL BLUE cores:

– most efficient solution for motor/generator bearing protection above 500kW

– by far the best value for the money compared to expensive ceramic bearings

– can easily be re-tooled/added to extisting installations

– is a proven solution due to many thousands of installations in Europe.

Several of the leading European Wind Mill manufacturers have been convinced by the concept of COOL BLUEand they have introduced this method as their standard for generator bearing protection.