As MH&W International continuously strives to be the leader for offering powerful solutions in the magnetics industry, MH&W has partnered with a leading OEM supplier of amorphous cores, custom nanocrystalline cores, and 80% nickel iron alloy cores. The core configurations include toroid’s, gapped toroid’s, cut cores, and specialty stampings. With the addition of these products, MH&W will be able to offer the marketplace competitive prices on low frequency magnetics designs in addition to the high frequency magnetics designs currently being supported.

Fe-based Amorphous Ribbon

Applications:

- Medium-frequency transformer cores in heating equipment.

- Toroidal gapless cores as SMPS output inductors and differential input inductors.

- Toroidal gapless cores as noise prevention chokes in car audio and navigation systems.

- Toroidal gap cores for PFC used in air conditioning and plasma TV.

- High-frequency rectangular cut cores as output inductors and transformers in SMPS, UPS, etc.

- Toroidal gapless cores as pulse transformers for driving IGBTs, MOSFETs, and GTOs.

- Amorphous stators and rotors in high power density speed-variable electric.

Characteristics:

- High saturation induction of 1.56 Tesla-Reducing component volume.

- Low coercivity – Increasing component efficiency.

- Low core loss – Reducing temperature rise in devices.

- Variable permeability by different heat treatments – Satisfying various application requirements.

- Excellent thermal stability – Highest service temperature of 130°C.

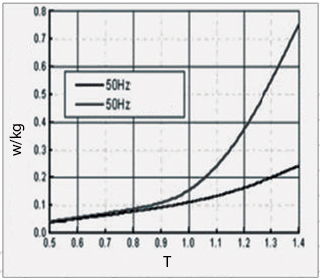

Power Frequency loss and excitation Power after annealing with Longitudinal Magnetic Field

Power Frequency loss and excitation Power after annealing with Longitudinal Magnetic Field

Physical Properties:

| Saturation Induction (Bs) | 1.56T | Hardness Hv | 960kg/mm2 |

| Curie Temperature (Tc) | 410 °C | Density | 7.18g/cm3 |

| Crystallization Temperature (Tx) | 535 °C | Resistivity | 130 µ Ω-cm |

| Saturation Magnetostriction | 27 X 10-6 |

Comparison of characteristics between

Fe-based Amorphous ribbon and cold-rolled silicon steel sheet

| Performance | Amorphous | Silicon Steel |

| Saturation Magnetic Inductance (T) | 1.56 | 2.03 |

| Coercivity (A/m) | <4 | <30 |

| Maximum Permeability | >25 X 104 | 4 X 104 |

| Core Loss (W/kg) | 50Hz, 1.3T, P<0.2 | 50Hz, 1.7T, P=1.2 |

| Magnetizing Power (VA/kg) | 50Hz, 1.3T, P<0.5 | 50Hz, 1.7T, P<0.83 |

| Stacking Factor | 0.84 | 0.95 |

| Magnetostriction (X10-6) | 27 | n/a |

| Resistivity (µ Ω-cm) | 130 | 45 |

| Density (g/cm3) | 7.18 | 7.65 |

| Crystallizationi Temperature (°C) | 535 | n/a |

| Curie Temperature (°C) | 415 | 746 |

| Strength (Mpa) | 1500 | 343 |

| Hardness (HV) | 900 | 181 |

| 300 | 300 | 300 |

Specifications:

| Width (mm) | Thickness (µm) | Manufacturing Method |

| 5 ± 0.05 | 25 ± 2 | Slitted Ribbon |

| 8 ± 0.05 | 25 ± 2 | Slitted Ribbon |

| 10 ± 0.05 | 25 ± 2 | Slitted Ribbon |

| 15 ± 0.05 | 25 ± 2 | Slitted Ribbon |

| 20 ± 0.1 | 25 ± 2 | Slitted Ribbon |

| 25 ± 0.1 | 25 ± 2 | Slitted Ribbon |

| 30 ± 0.1 | 25 ± 2 | Slitted Ribbon |

| 40 ± 0.1 | 25 ± 2 | Slitted Ribbon |

| 50 ± 0.1 | 25 ± 2 | Slitted Ribbon |

| 60 ± 1 | 25 ± 2 | Casted Ribbon |

| 100 ± 1 | 25 ± 2 | Casted Ribbon |

| 142 ± 1 | 25 ± 2 | Casted Ribbon |

| 170 ± 1 | 25 ± 2 | Casted Ribbon |

Note: Other specifications can be provided based on customer requirements